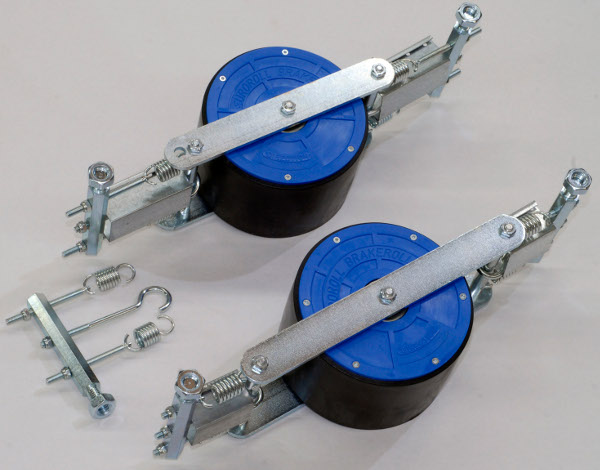

Braking rollers control the speed at which goods are transported upon the roller rails. Their main intended use is for transport of pelleted goods, nevertheless other products may also benefit from such systems.

This is achieved by epicyclic gear system which presses on the roller after using a centrifugal plate thus reducing the rollers rotation. In deciding on the distance between braking rollers and their particular type one has to take into account the following:

- roller track construction and maximum load capacity

- track fall slope

- transported product characteristics (dimension, weight, shape etc…)

- resistance value of braking roller

- work environment (humidity, temperature etc…)

An optimal solution is installing one braking roller per one pallet space. Through this we are able to achieve constant feed speed. Feed speed should not exceed 0.3 m/sec, but correctly adjusted brae setting 0.1-0.2 m/sec is achievable.

Send Inquiry