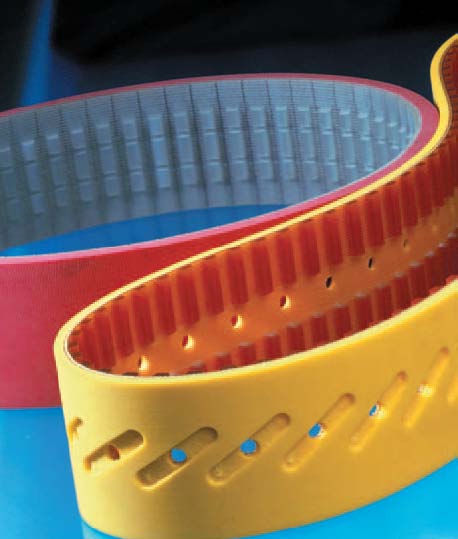

Flat belts, conveyor belts and toothed belts can be modified using various technological processes as a result; you can acquire properties that make these belts resistant to chemical and physical factors. These are manufactured in accordance with the requirements of the use of certain technological processes-the most popular among them are mechanical processes, bonding and welding.

Scribing and cutting

Facilitates flexibility and performance with a minimum diameter of rollers

Perforation and cutting

Thanks to vacuity keeps products on top of the surface

Surface coating

Through bonding and welding materials achieve correct slipperiness and not adhesion

Correct Form

Helps control and guide products during production process.

THERE IS OVER 50 DIFFERENT PROFILES AVILABLE

Application