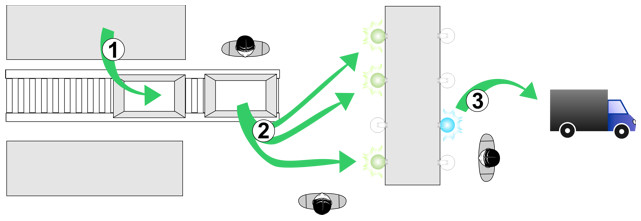

First Option – illuminated operator panels are used to mark order batches in picking system storage pods. In this instance each batch represents one order. Products are taken from the warehouse pods and put into crates in sheer amounts (total amount of product positions for all orders) and transported to order picking destination – in this case location where Put-to-Light/Pick-by-light system is operational.

1) Product is taken from the warehouse stillage pod and placed into crates (one crate for each specific product choice). Amount of product in crates is dependant on current given picked order batches.

2) Sorting base receives crates transported on the conveyor. Operator removes crate off the conveyor and then places correct amount of products into given storage pods, confirming the action by pressing operator button under relevant pod. Control light located on the panel under the pod ignites when WMS system sends a signal, thus informing the operator on intended pod placement of product.

3) Information on picked order is signalled on the other side of the pod stallage via a control light. Operator receives order and confirms it by pressing a button; operator prepares picked order for transport.

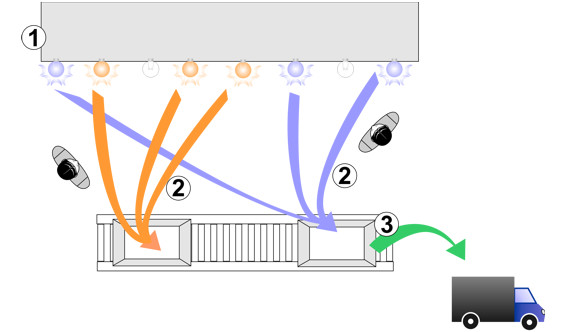

Second Option – used in narrow product range (e.g. 100 different prod). In this option order picking is done right at the pod stillage.

1) Operator selects order to be picked (selection made from list of orders visible on the panel or computer screen).Once selection is made signal is sent to the Pick-by-Light system, installed in the pod stillage. Each pod consists of a unique id. Signal panel module is located beneath each specific pod. Acceptance of a given order ready to be picked is announced through control lights and the amount of stock needed for picking under each category in relation to the order is displayed.

2) Products are collected and confirmed by the operator through a pressed button under neath each pod from which it was taken. If required, more than one operator can pick orders at a particular. Orders simultaneously completed by two different operators are identified by assigning different light colour to specific operators or pick orders.

3) Depending on a chosen solution, an operator has a choice of either complete the order by directing it to pack and send or manually completes that particular task.

Pick-by-light and Put-to-light solutions presented are compatible with already present IT Systems in a company. Needed requirement, is existence of WMS, which provides information and details regarding orders to be prepared.